Filament Spectrum PA6 Neat 1.75mm BK 0.75kg

Filament Spectrum PA6 Neat BK

High temperature poliamide

Filament Spectrum PA6 Neat BK is a new, high-temperature PA6-based construction material in black colour. A major feature of the PA6 Neat is its increased mechanical strength as...

Description

Filament Spectrum PA6 Neat BK

High temperature poliamide

Filament Spectrum PA6 Neat BK is a new, high-temperature PA6-based construction material in black colour. A major feature of the PA6 Neat is its increased mechanical strength as compared to other plastics. The material also features exceptional thermal properties, chemical resistance to oils and lubricants, relatively high resistance to corrosion stimulators and good electrical insulation properties as compared to unmodified PA6 or PA66.

Parts made of Spectrum PA6 Neat BK allow for long-term operation at elevated temperatures up to 120°C (20.000h) and up to 160°C for a short-time operation (max. 200h), while maintaining sufficient mechanical properties. Filament PA6 Neat is characterized by a low linear processing shrinkage (0.3%) and a reduced water absorption (<0.3%, 23 ° C / 24h). The above features make it an excellent filament for a professional user to make solid prints.

To attain the very attractive properties of PA6 Neat BK, as regards the technical aspects, you need to follow the basic storage rules for such materials (in a dry and dark place with humidity below 15%). To obtain the best parameters of the printed object possible, it is recommended to dry the material prior to work.

Tip: It is recommended to print using a heated chamber.

Key features:

- low linear processing shrinkage (0.3%)

- high temperature up to 160°C for short-time operation (max. 200h)

- high temperature up to 120°C for long-time operation (20.000h)

- heat distortion temperature – HDT A 90°C (ISO 75)

- water absorption below 0.3% (23°C / 24h)

- high creep resistance

- good tribological properties, including dry friction conditions such as in slide bearing

- chemical resistance to lubricants and oils

Applications:

- production of gear wheels and racks, slide bearings, sweep-off gears and guide rolls operated in elevated temperatures up to 120°C on a prolonged basis and up to 160°C on a short-time basis

- all types of ring and plate seals with an increased chemical and corrosion resistance

- end-use parts

- tooling

- functional prototyping

- industrial modelling

Packaging

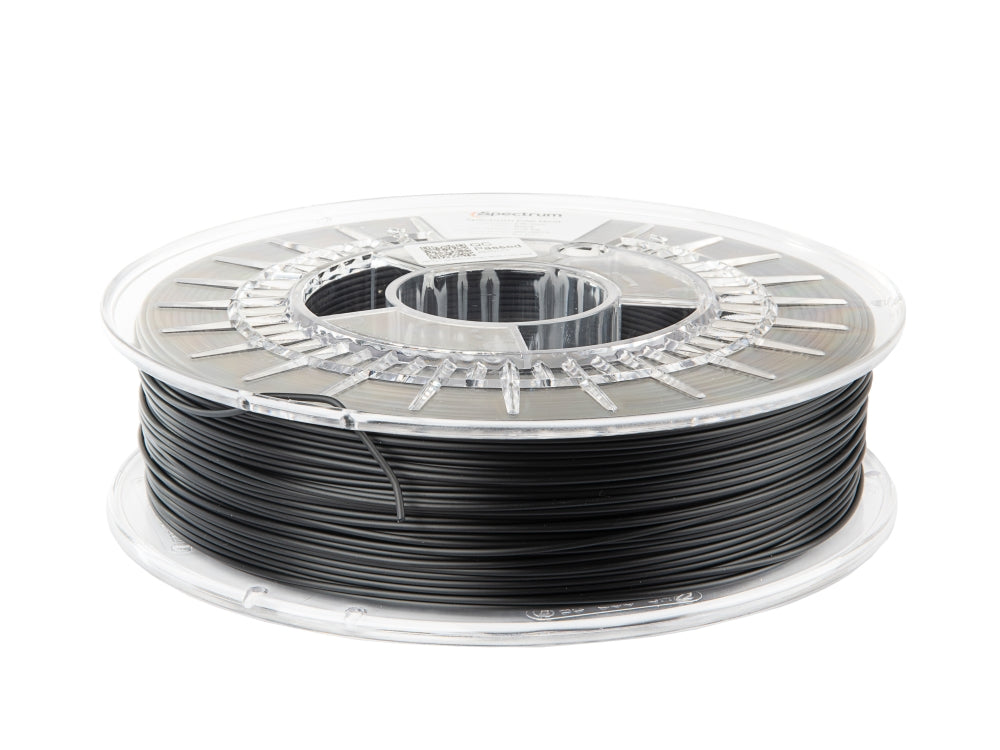

Filament is reeled on the neat, transparent spool. Each spool contains information on the type of material, diameter and recommended printing temperature. Filament is vacuum-packed in an aluminiumvacuum bag with ZIP lock with a moisture absorber. Whole product packed in the original, folied Spectrum Filaments packaging.

Specification

General information

Specification

Technical data

How to print?

Spool dimensions

250

44

140

52

120

Plastic

Transparent

250

44

140

52

80

Cardboard

-

500

55

200

52

240

Plastic

Transparent

750

55

200

52

240

Plastic

Transparent

1000

67

200

52

260

Plastic

Transparent

1000

67

200

52

180

Cardboard

-

2000

100

300

52

600

Plastic

Black

2000

100

300

52

420

Cardboard

-

4500

100

350

52

780

Plastic

Black

8000

167

355

36

1020

Plastic

Black

Each spool is sealed. We recommend storing filaments in a cool (15-25°C) and dry place.

Reviews

Description

Filament Spectrum PA6 Neat BK

High temperature poliamide

Filament Spectrum PA6 Neat BK is a new, high-temperature PA6-based construction material in black colour. A major feature of the PA6 Neat is its increased mechanical strength as compared to other plastics. The material also features exceptional thermal properties, chemical resistance to oils and lubricants, relatively high resistance to corrosion stimulators and good electrical insulation properties as compared to unmodified PA6 or PA66.

Parts made of Spectrum PA6 Neat BK allow for long-term operation at elevated temperatures up to 120°C (20.000h) and up to 160°C for a short-time operation (max. 200h), while maintaining sufficient mechanical properties. Filament PA6 Neat is characterized by a low linear processing shrinkage (0.3%) and a reduced water absorption (<0.3%, 23 ° C / 24h). The above features make it an excellent filament for a professional user to make solid prints.

To attain the very attractive properties of PA6 Neat BK, as regards the technical aspects, you need to follow the basic storage rules for such materials (in a dry and dark place with humidity below 15%). To obtain the best parameters of the printed object possible, it is recommended to dry the material prior to work.

Tip: It is recommended to print using a heated chamber.

Key features:

- low linear processing shrinkage (0.3%)

- high temperature up to 160°C for short-time operation (max. 200h)

- high temperature up to 120°C for long-time operation (20.000h)

- heat distortion temperature – HDT A 90°C (ISO 75)

- water absorption below 0.3% (23°C / 24h)

- high creep resistance

- good tribological properties, including dry friction conditions such as in slide bearing

- chemical resistance to lubricants and oils

Applications:

- production of gear wheels and racks, slide bearings, sweep-off gears and guide rolls operated in elevated temperatures up to 120°C on a prolonged basis and up to 160°C on a short-time basis

- all types of ring and plate seals with an increased chemical and corrosion resistance

- end-use parts

- tooling

- functional prototyping

- industrial modelling

Packaging

Filament is reeled on the neat, transparent spool. Each spool contains information on the type of material, diameter and recommended printing temperature. Filament is vacuum-packed in an aluminiumvacuum bag with ZIP lock with a moisture absorber. Whole product packed in the original, folied Spectrum Filaments packaging.

Specification

General information

Specification

Technical data

How to print?

Spool dimensions

| Content [g] | Width [mm] | Outer diameter [mm] | Inner diameter [mm] | Weight empty [g] | Material | Spool color |

|---|---|---|---|---|---|---|

| 250 | 44 | 140 | 52 | 120 | Plastic | Transparent |

| 250 | 44 | 140 | 52 | 80 | Cardboard | - |

| 500 | 55 | 200 | 52 | 240 | Plastic | Transparent |

| 750 | 55 | 200 | 52 | 240 | Plastic | Transparent |

| 1000 | 67 | 200 | 52 | 260 | Plastic | Transparent |

| 1000 | 67 | 200 | 52 | 180 | Cardboard | - |

| 2000 | 100 | 300 | 52 | 600 | Plastic | Black |

| 2000 | 100 | 300 | 52 | 420 | Cardboard | - |

| 4500 | 100 | 350 | 52 | 780 | Plastic | Black |

| 8000 | 167 | 355 | 36 | 1020 | Plastic | Black |

Each spool is sealed. We recommend storing filaments in a cool (15-25°C) and dry place.

Reviews

Do you need help? Do you have any questions?

Ask a question and we'll respond promptly, publishing the most interesting questions and answers for others.

High quality filaments

Wide portfolio consisting of over 80 filaments with a versatile range of properties and applications, divided into three segments: desktop easy-to-use, industrial grade and high performance.

European manufacturing

All filaments from our portfolio are in-house made. We use modern production lines equipped with non-standard solutions to obtain highest quality final product.

technical support

Our qualified support team helps at every stage from material selection to the 3D printing process.