Filament Spectrum ASA Kevlar 1.75mm NAT 0.75kg

ASA Kevlar by Spectrum Filaments

High durability in production applications

Spectrum ASA Kevlar filament is a technical composite material based on a combination of ASA copolymer and aramid fibres. The aim of producing composite materials...

Filament Spectrum ASA Kevlar 1.75mm NAT 0.75kg

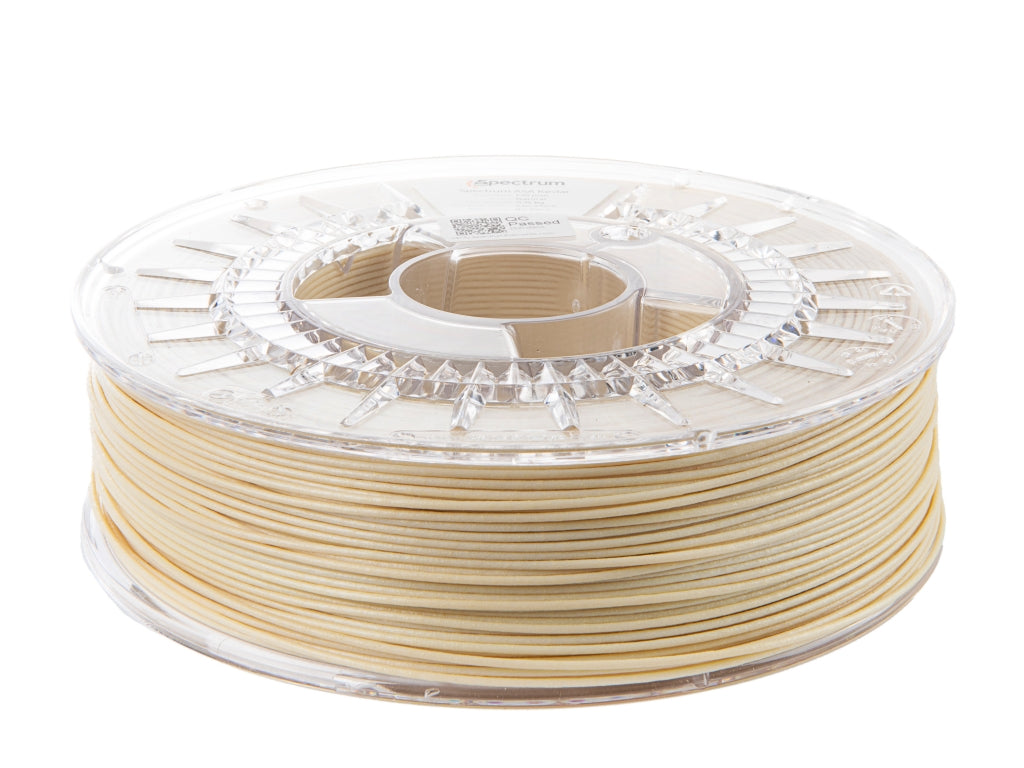

Spectrum color name: Natural

$69.00 CAD

Description

ASA Kevlar by Spectrum Filaments

High durability in production applications

Spectrum ASA Kevlar filament is a technical composite material based on a combination of ASA copolymer and aramid fibres. The aim of producing composite materials by combining different types materials is to impart new properties, previously unattainable for separate components. As a base for the composite, we used the ASA copolymer, well known for its high resistance to weather conditions, combining it with aramid, which is used to make some of the strongest synthetic fibres.

Aramid fibres, mainly known as Kevlar, are used to manufacture highly damage-resistant items such as bulletproof vests, helmets and speaker membranes. Aramid fibres do not fracture easily under stress (unlike glass and carbon fibres), instead they experience shear fracture and tearing - which gives them high resistance to damage.

Aramid itself is a not a particularly UV-resistant material, coating it and - in a way - protecting in the ASA polymer, highly resistant to this factor, guarantees a long life for the fibres and the entire composite. Unlike carbon and glass fibres, Kevlar fibres exhibit significantly less abrasion of the printer nozzle, which is not insignificant for the processing costs of printing. The use of fibre structures helps reduce material shrinkage when printing, making it possible to produce large-scale models.

With our new filament, Kevlar is now also finding its place in 3D printing technology. Components printed from Spectrum ASA Kevlar can be used in applications that require sunlight resistance and high impact strength (e.g. bumpers, protection, etc.). The aramid fibre makes for a rougher outer surface of the prints, making them more matt and, therefore, more aesthetically pleasing than classic ASA.

Key features:

- Aramid fibers reinforced

- HDT thermal resistance - 89°C

- Vicat softening point - 94°C

- good aging resistance

- very strong impact resistance

- relatively high chemical resistance

- UV resistance

- printable on desktop devices without a heated chamber

- matt print surface

- perfect bonding of the layers

Applications:

- functional prototype,

- production tooling

- manufacture of fixtures and assembly tools

- manufacture of components exposed to impact

- components that need high resistance to outdoor exposure

Packaging

Filament is reeled on the neat, transparent spool. Each spool contains information on the type of material, diameter and recommended printing temperature. Filament is vacuum-packed with a moisture absorber. Whole product packed in the original, folied Spectrum Filaments packaging.

Specification

General information

Specification

Technical data

How to print?

Spool dimensions

250

44

140

52

120

Plastic

Transparent

250

44

140

52

80

Cardboard

-

500

55

200

52

240

Plastic

Transparent

750

55

200

52

240

Plastic

Transparent

1000

67

200

52

260

Plastic

Transparent

1000

67

200

52

180

Cardboard

-

2000

100

300

52

600

Plastic

Black

2000

100

300

52

420

Cardboard

-

4500

100

350

52

780

Plastic

Black

8000

167

355

36

1020

Plastic

Black

Each spool is sealed. We recommend storing filaments in a cool (15-25°C) and dry place.

Reviews

Description

ASA Kevlar by Spectrum Filaments

High durability in production applications

Spectrum ASA Kevlar filament is a technical composite material based on a combination of ASA copolymer and aramid fibres. The aim of producing composite materials by combining different types materials is to impart new properties, previously unattainable for separate components. As a base for the composite, we used the ASA copolymer, well known for its high resistance to weather conditions, combining it with aramid, which is used to make some of the strongest synthetic fibres.

Aramid fibres, mainly known as Kevlar, are used to manufacture highly damage-resistant items such as bulletproof vests, helmets and speaker membranes. Aramid fibres do not fracture easily under stress (unlike glass and carbon fibres), instead they experience shear fracture and tearing - which gives them high resistance to damage.

Aramid itself is a not a particularly UV-resistant material, coating it and - in a way - protecting in the ASA polymer, highly resistant to this factor, guarantees a long life for the fibres and the entire composite. Unlike carbon and glass fibres, Kevlar fibres exhibit significantly less abrasion of the printer nozzle, which is not insignificant for the processing costs of printing. The use of fibre structures helps reduce material shrinkage when printing, making it possible to produce large-scale models.

With our new filament, Kevlar is now also finding its place in 3D printing technology. Components printed from Spectrum ASA Kevlar can be used in applications that require sunlight resistance and high impact strength (e.g. bumpers, protection, etc.). The aramid fibre makes for a rougher outer surface of the prints, making them more matt and, therefore, more aesthetically pleasing than classic ASA.

Key features:

- Aramid fibers reinforced

- HDT thermal resistance - 89°C

- Vicat softening point - 94°C

- good aging resistance

- very strong impact resistance

- relatively high chemical resistance

- UV resistance

- printable on desktop devices without a heated chamber

- matt print surface

- perfect bonding of the layers

Applications:

- functional prototype,

- production tooling

- manufacture of fixtures and assembly tools

- manufacture of components exposed to impact

- components that need high resistance to outdoor exposure

Packaging

Filament is reeled on the neat, transparent spool. Each spool contains information on the type of material, diameter and recommended printing temperature. Filament is vacuum-packed with a moisture absorber. Whole product packed in the original, folied Spectrum Filaments packaging.

Specification

General information

Specification

Technical data

How to print?

Spool dimensions

| Content [g] | Width [mm] | Outer diameter [mm] | Inner diameter [mm] | Weight empty [g] | Material | Spool color |

|---|---|---|---|---|---|---|

| 250 | 44 | 140 | 52 | 120 | Plastic | Transparent |

| 250 | 44 | 140 | 52 | 80 | Cardboard | - |

| 500 | 55 | 200 | 52 | 240 | Plastic | Transparent |

| 750 | 55 | 200 | 52 | 240 | Plastic | Transparent |

| 1000 | 67 | 200 | 52 | 260 | Plastic | Transparent |

| 1000 | 67 | 200 | 52 | 180 | Cardboard | - |

| 2000 | 100 | 300 | 52 | 600 | Plastic | Black |

| 2000 | 100 | 300 | 52 | 420 | Cardboard | - |

| 4500 | 100 | 350 | 52 | 780 | Plastic | Black |

| 8000 | 167 | 355 | 36 | 1020 | Plastic | Black |

Each spool is sealed. We recommend storing filaments in a cool (15-25°C) and dry place.

Reviews

Do you need help? Do you have any questions?

Ask a question and we'll respond promptly, publishing the most interesting questions and answers for others.

High quality filaments

Wide portfolio consisting of over 80 filaments with a versatile range of properties and applications, divided into three segments: desktop easy-to-use, industrial grade and high performance.

European manufacturing

All filaments from our portfolio are in-house made. We use modern production lines equipped with non-standard solutions to obtain highest quality final product.

technical support

Our qualified support team helps at every stage from material selection to the 3D printing process.